In this article, we will provide a concise exploration of the key parameters used to assess fabric quality. Additionally, we will explain the tests that determine each of these parameters and how to interpret the results.

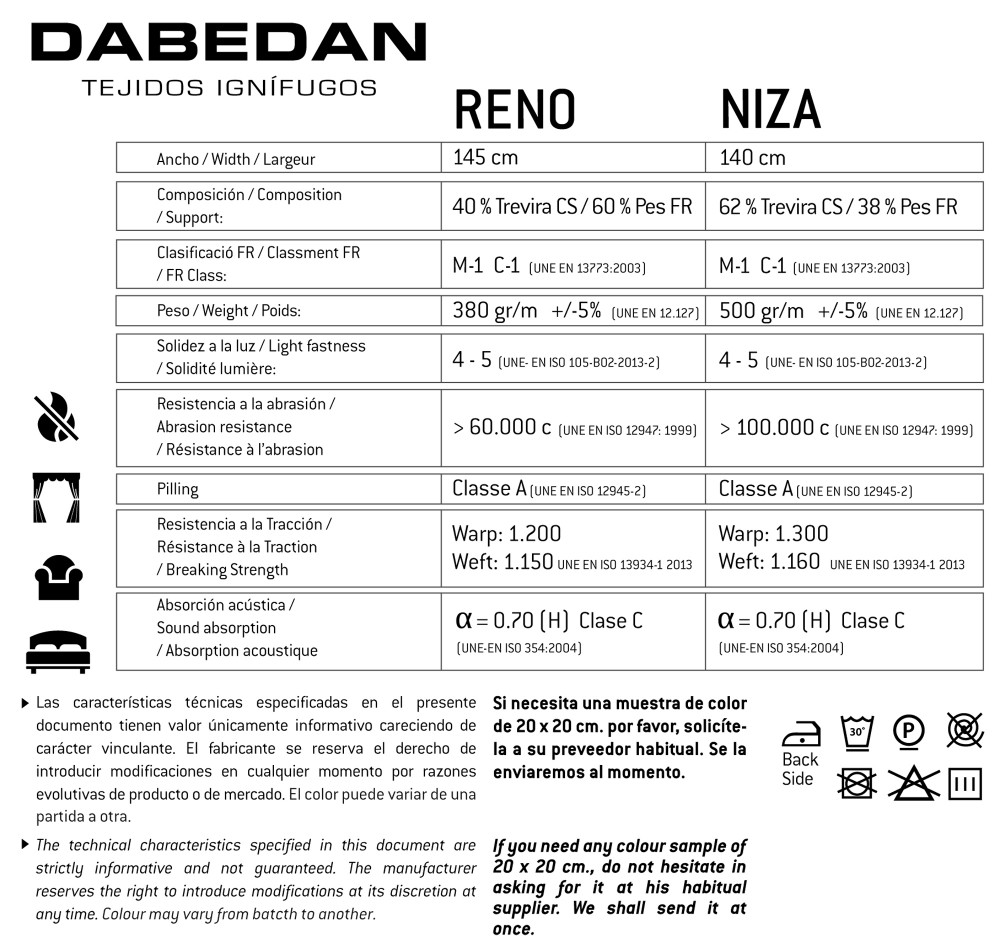

At DABEDAN, the quality of our fabrics is a top priority. We subject our products to rigorous tests and trials to ensure our customers superior quality.

1-WEIGHT PER SQUARE METER

The weight or grammage of the fabric is a crucial indicator of its quality. It is used to verify the proper manufacturing of fabrics, as it determines the amount of material used. It is expressed in grams per square meter and can also be converted into weight per linear meter.

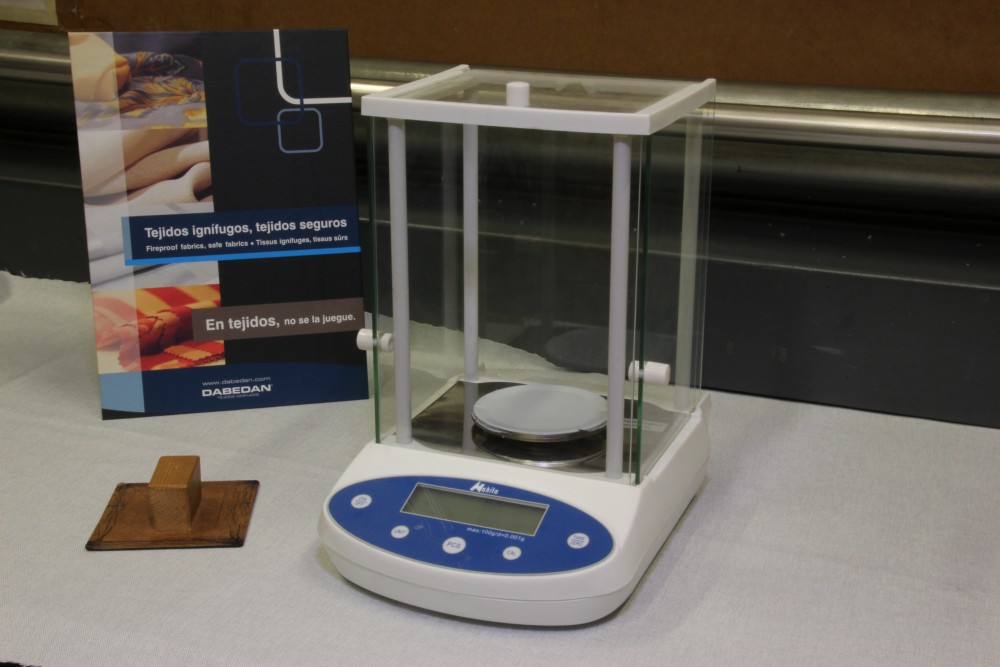

The test to determine weight is simple and is performed with a balance and a sample cutter. The sample is cut into a circular shape equivalent to a 10×10 centimeter square. After cutting the sample, it is weighed directly on the balance. The obtained data is multiplied by one hundred to get the weight per square meter, following the UNE 12127 standard.

2-WARP AND WEFT DENSITY

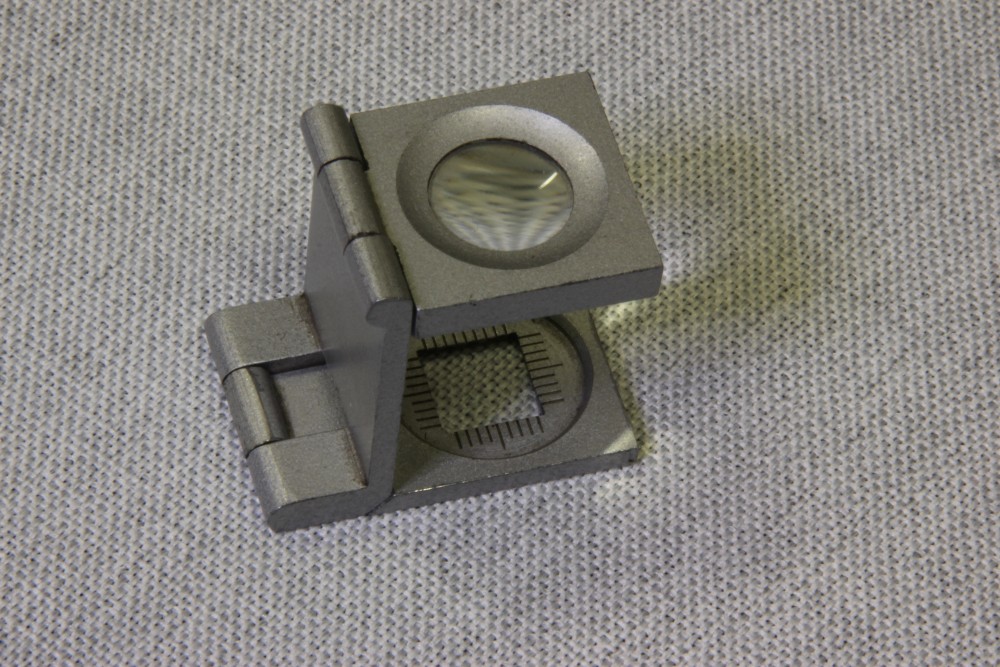

The density of fabrics refers to the number of threads and picks per centimeter. This measurement is made by observing and directly counting the threads and picks in one centimeter of fabric. A thread counter is used to facilitate the task.

3-FABRIC WEAVE

The weave is defined as the order of interlacing of warp and weft threads in woven fabrics.

Checking the fabric weave is important to control the correct execution of the weaving process. The check is made through direct observation of the samples. The device used is the thread counter.

The testing standard is UNE 40017 and 40161. It describes how to prepare the sample and the method consisting of unweaving the fabric thread by thread, observing the placement of the weft relative to the warp, and noting these developments on graph paper.

4-RESISTANCE TO PILLING FORMATION

The so-called “Pilling” effect is a phenomenon known in the textile field. It comes especially in textiles composed of fibers, particularly if these items contain synthetic fibers.

Pilling appears on the fabric’s surface in the form of variable-sized pills produced as a result of the physical-mechanical process that garments undergo during use, especially due to friction in certain areas of the fabric with itself and/or external elements. Pilling gives the fabric an unpleasant appearance, constituting the first symptom of aging and wear of the fabric.

Measurement is carried out with abrasion testers.

There are finishing operations and finishes that reduce the tendency to pilling:

Thermofixation: This process fixes the position and twist of the fibers, preventing them from protruding together.

Singeing: This operation eliminates the ends of the fibers from the fabric’s surface.

Hot Calendering: Produces flattening and smoothing of the fabric’s surface, as well as a fiber-fixing effect, reducing their migration to the fabric’s surface.

Shearing: A process in which the protruding fibrils from the fabric are cut, making it difficult for them to entangle.

Resins: Trap fibers, preventing their migration to the surface of the fabric.

Silicones: Decrease abrasion of the fabric surface, delaying pilling.

The equipment used is the “Abrasion Tester”. Composed of a static plate supporting the abrasive material and a piece holding the fabric sample to be measured. This movable piece cycles over the abrasive material. The apparatus is completed with a cycle counter.

The most commonly used equipment is known as the Martindale.

Interpretation of Results:

5-No visual change.

4-Superficial fuzziness and occasional pilling.

3-Moderate formation of pilling.

2-Visible and abundant pilling.

1-Very intense pilling over the entire surface.

5-RESISTANCE TO ABRASION

Similar to pilling, the equipment used is the Abrasion Tester, with the Martindale being the most commonly used.

To determine the abrasion resistance of fabrics, the UNE-EN-ISO-12.947-2 standard is used, specifying all the necessary parameters for the test, as well as the materials and equipment required.

The methodology is mainly based on determining the number of cycles needed to break a certain number of threads that make up the fabric.

The test result is expressed in cycles.

The abrasive element is a standard wool fabric.

Interpretation of Results:

The result is expressed by the number of cycles the fabric has endured until the corresponding number of threads break. There are general limits, typically 100,000 cycles. If the fabric withstands this limit without breaking, the test is stopped, and the result is expressed as a resistance exceeding 100,000 cycles.

For example, DABEDAN’s HERA Velvet exceeds 100,000 abrasion cycles.

6-TENSILE STRENGTH

Tensile strength is particularly important for determining the fabric’s intended use. For fabrics with special applications, knowledge of this value determines the fabric’s suitable use.

Another parameter analyzed in this test is the elongation of the fabric when a tensile force is applied, essentially the lengthening of the fabric.

Various concepts are linked to tensile strength:

– Elasticity or elastic elongation: The length a fabric experiences when subjected to tensile force, such that when the effort ceases, the fabric regains its initial length.

– Elongation until rupture: The maximum length a fabric experiences when subjected to tensile force and this force does not cease until rupture occurs.

– Permanent deformation: Length acquired by the fabric when the tensile force ceases. It is measured by the difference between elastic elongation and rupture elongation.

The equipment used is the Dynamometer, consisting mainly of a pair of clamps. One clamp is fixed, and the other is responsible for exerting the force necessary until the fabric breaks.

It is connected to a computer system responsible for recording the values obtained for both the force applied until the fabric breaks and the elongation suffered by the fabric.

There are other fabric parameters to measure its quality, such as:

– Tear resistance.

– Wrinkle formation.

– Air and water impermeability.

– Colourfastness.

We hope that after reading this article, you have a better understanding of how to assess fabric quality.

Subscribe to our newsletter

Receive all communications in your email to stay up to date with our news, as well as news and advice about the sector.

Latest published articles

Do you need advice?

We collaborate with you to develop custom designs tailored to the needs of each project, creating the fabric according to aesthetic, quality, or usage requirements.

Get in touch with us, and we will advise you on our products, or request a free sample.