Fire Resistance Classification: RENO Velvet and Dim Outs.

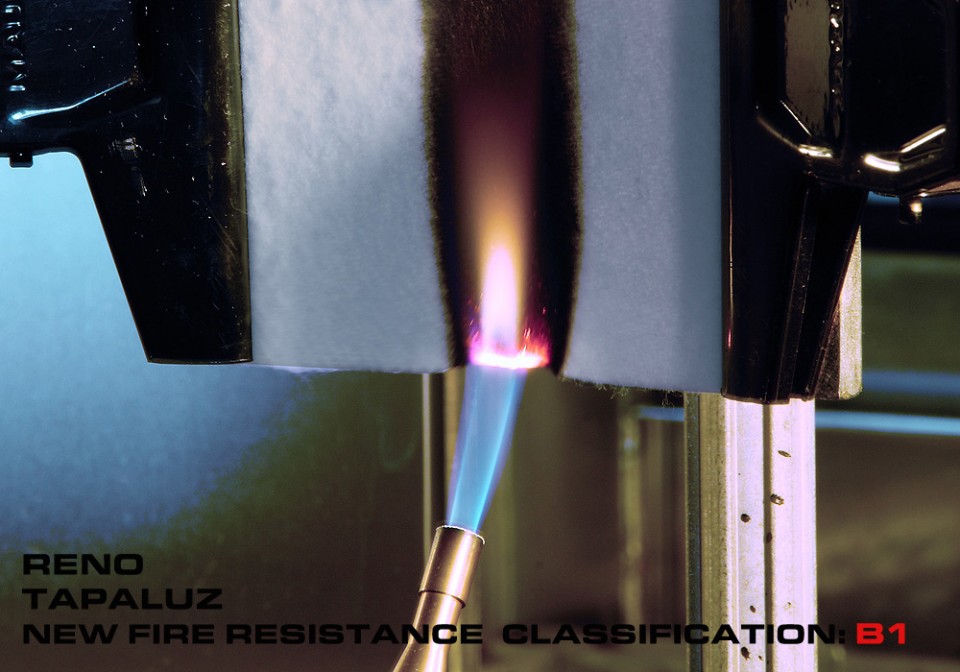

We are pleased to announce that both RENO Velvet and TAPALUZ Dim Outs have achieved the German B1 fire reaction classification according to DIN-4102 standard.

Thus, in addition to the previously obtained Spanish (C-1) and French (M-1) fire reaction classifications, the German classification (B-1) is now added.

Flammability tests are crucial in the textile industry, as they have significant implications for safety in case of fire.

tatistically, the leading cause of deaths in fires is directly related to the accidental ignition of vertical textile decoration and textiles in general. For this reason, fabrics must undergo rigorous fire resistance testing to ensure safer indoor spaces.

Unfortunately, there is no universally adopted standard for the flammability of fabrics on vertical surfaces, and the variety of regulations in force internationally reflects different approaches to this issue.

GERMANY

In Germany, decorative fabrics are approved according to the DIN-4102 standard established by the Deutsches Institut ARY Bautechnik.

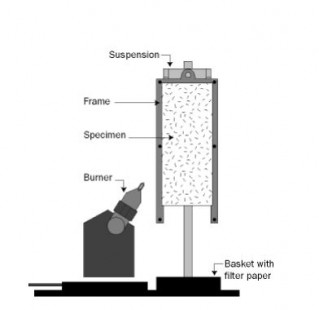

DIN 4102 Part 1 – Kleinbrenner (B2)

The fabric sample is vertically suspended, and a 20mm flame is applied for 15 seconds on both sides of the fabric and at the edges.

Reference lines are marked on the fabric, which achieves the B2 classification if the flame does not reach the reference marks within 20 seconds on any sample.

Five samples are tested, placing a filter paper under each sample to determine the production of drop formation.

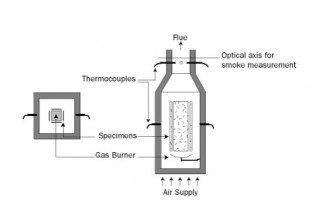

DIN 4102 Parts 15/16 – Brandschacht (B1)

Known as the “Brandschacht test,” this is the main testing method in Germany that measures

fire reaction and is considered the highest flammability standard in the country for fabrics.

The term Brandschacht, literally “fire shaft,” refers to the test apparatus itself, which consists of

a vertical support frame in the form of squares, equipped with a gas burner. Four fabric samples are vertically placed on a support frame and subjected to flames for 1 minute. At the same time, a constant, uniform

flow of air is blown into the Brandschacht from below.

To evaluate the test, the temperature of the smoke gas is considered, as well as the average residual length of the sample. Residual length refers to the part of the fabric that has escaped burning.

To be classified as B1, the sample fabric must demonstrate:

– An average residual length of no less than 150 mm, with no specimen burning completely.

– A smoke gas temperature averaging less than 200°C.

Both Reno Velvet and Dim Outs from DABEDAN have obtained the B1 classification according to DIN 4102-1. This certifies them as fabrics suitable and safe for use as vertical textile decoration in buildings in Germany, contributing to a more protected indoor environment.

DABEDAN, FLAME RETARDANT FABRICS, SAFE FABRICS

Subscribe to our newsletter

Receive all communications in your email to stay up to date with our news, as well as news and advice about the sector.

Latest published articles

Do you need advice?

We collaborate with you to develop custom designs tailored to the needs of each project, creating the fabric according to aesthetic, quality, or usage requirements.

Get in touch with us, and we will advise you on our products, or request a free sample.