Abrasion resistance and its importance in various applications

In the world of textiles, durability is key. Fabrics face constant wear and tear, and their ability to withstand abrasion directly impacts their lifespan and performance. This blog post dives into the concept of abrasion resistance, exploring its significance in various applications and how it contributes to high-quality fabrics.

What is abrasion resistance?

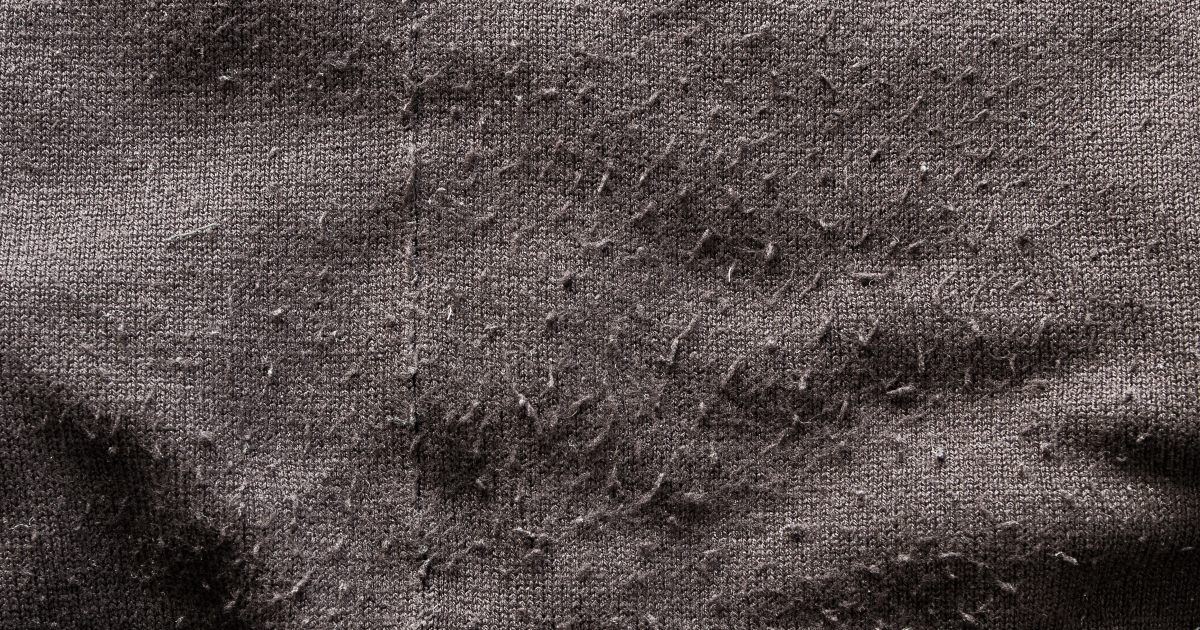

Abrasion resistance is the ability of a material to withstand wear and tear from continuous rubbing or friction. It’s a critical quality in textiles that determines how long apparel, furnishings, and industrial textiles can resist surface wear. High abrasion resistance is often associated with fabrics that can endure tough conditions without losing integrity or appearance.

Types of abrasion

– Flat Abrasion: This occurs when fabric rubs against another flat surface.

– Edge Abrasion: Involves the fabric being worn down along its edges.

– Flex Abrasion: Happens when fabric is repeatedly bent or flexed.

Testing methods: methods used to test abrasion resistance

Fabric manufacturers rely on standardized abrasion testing methods to evaluate a fabric’s resistance. These tests simulate real-world wear and tear to predict performance. The Martindale Test is commonly employed and uses the UNE-EN-ISO-12.947-2 standard, which specifies all necessary parameters for conducting the test, including materials and equipment. Other common testing methods include the Taber Test, which uses a rotating disc with abrasive wheels, and the Wyzenbeek Test, specific to the United States, involving rubbing fabric against a standard abrasive surface for a set number of cycles. For complete technical information, refer to ‘Abrasion Resistance: The Full Story‘ by The Association for Contract Textiles.

Interpretation of Results

The outcome of the abrasion test is quantified by the number of cycles the fabric endures until the breakage of the specified number of threads. Generally, there is a threshold of 100,000 cycles; if the fabric withstands this limit without breaking, the test is halted, and the result is expressed as resistance exceeding 100,000 cycles. For example, our Velvets Hera, Moon, Niza, and our upholstery fabric lines Nina and Regina, all surpass this threshold, showcasing their superior durability.

You can learn more about ‘test and key parameters at Dabedan‘ by reading this article.

Importance of abrasion resistance in fabrics

High abrasion resistance offers several benefits for fabrics:

– Extending the life: Abrasion-resistant fabrics last longer, reducing the need for replacements and saving money in the long run.

– Maintaining aesthetics: Fabrics prone to abrasion quickly show signs of wear, like pilling, fading, or tearing. Abrasion-resistant fabrics retain their appearance for longer.

– Enhanced Performance: In specific applications, abrasion resistance is crucial. For instance, upholstery fabrics for high-traffic areas need to withstand constant use.

Impact of abrasion on fabric durability and longevity

Abrasion can reduce a fabric’s strength, cause pilling, and fade colours, significantly shortening the lifespan of the product. Understanding the abrasion resistance of fabrics helps manufacturers like Dabedan tailor their products to meet the demands of various applications, from fashion to industrial uses.

Types of abrasion resistance fabrics

Many high-quality fabrics prioritize abrasion resistance. Here are some examples:

– Nylon: Known for its strength and durability, nylon is a popular choice for activewear, backpacks, and luggage due to its excellent abrasion resistance.

– Polyester: Another synthetic fiber offering high abrasion resistance, polyester is commonly used in upholstery fabrics, workwear, and outdoor gear.

– Aramid fibers: These high-performance fibers, including Kevlar®, offer exceptional abrasion resistance and are often used in flame-retardant fabrics and protective clothing.

– Ultra-high-molecular-weight polyethylene (UHMWPE): This synthetic fiber boasts outstanding abrasion resistance and finds applications in bulletproof vests, cut-resistant gloves, and high-performance ropes.

Applications and Industries

Abrasion resistance plays a critical role in various industries:

– Apparel: Fabrics for outdoor clothing, workwear, sportswear, and luggage need high abrasion resistance to withstand daily use and harsh environments.

– Upholstery: Furniture fabrics in high-traffic areas require strong abrasion resistance to maintain their integrity and appearance.

– Industrial Textiles: Conveyor belts, filters, and tarpaulins benefit from abrasion resistance to function effectively in demanding settings.

– Safety Equipment: Fabrics used in cut-resistant gloves, protective gear, and bulletproof vests require exceptional abrasion resistance for user safety.

Abrasion resistant fabric examples

– Cordura: Widely used in military wear, backpacks, and heavy-duty gear.

– Dyneema: Offers high strength-to-weight ratios, suitable for extreme applications.

– Twaron: Similar to Kevlar, used in ballistic-rated body armor and protective clothing.

How to improve abrasion resistance in fabric

Improving a fabric’s abrasion resistance involves several strategies:

– Blending Fibers: Combining fibers like nylon and polyester can enhance the abrasion resistance.

– Coating and Treatments: Applying surface treatments or coatings can provide a protective layer that minimizes wear.

– Fabric Construction: Tighter weaves and higher densities in fabric construction can improve resistance.

Understanding and improving abrasion resistance are critical for fabric manufacturers like Dabedan. By focusing on high-quality, eco-friendly, and high-performance materials that withstand demanding environments, Dabedan ensures its products deliver great service and performance. Alargar la vida útil del tejido mediante tecnologías y métodos avanzados marca a Extending fabric longevity through advanced technologies and methods marks Dabedan as a leader in the textile industry, offering solutions that are not just effective but also innovative and sustainable.

Subscribe to our newsletter

Receive all communications in your email to stay up to date with our news, as well as news and advice about the sector.

Latest published articles

Do you need advice?

We collaborate with you to develop custom designs tailored to the needs of each project, creating the fabric according to aesthetic, quality, or usage requirements.

Get in touch with us, and we will advise you on our products, or request a free sample.